-40%

WUTA 3 in 1 Leather Groover Tool Set Adjustable Edge Crease Stitching Groover

$ 39.06

- Description

- Size Guide

Description

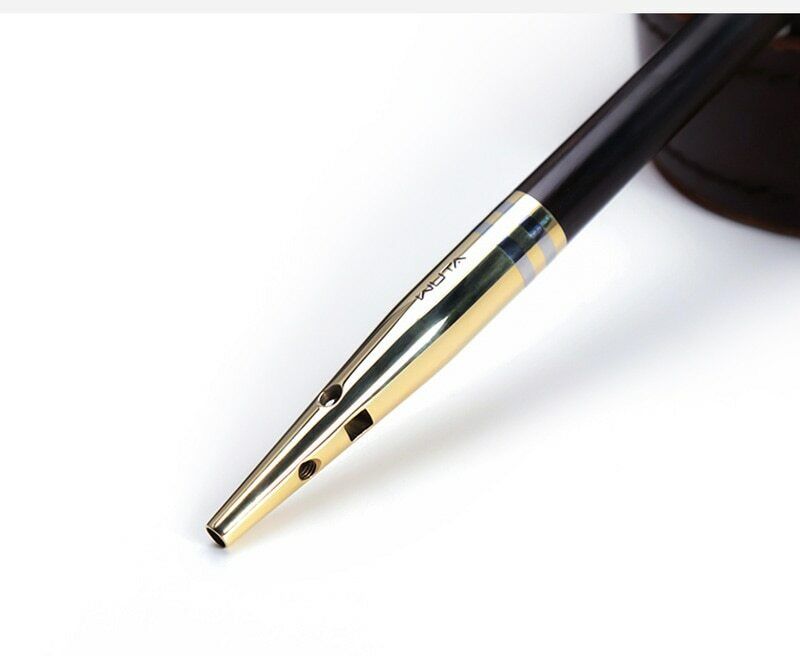

SpecificationName: Advanced Leather Groover Tool

Brand: WUTA

Material: M390 steel (cutter head) , ebony (handle) , brass (ferrule)

Hardness (cutter head) : 55HRC

Function: Adjust the distance between the groove and the leather edge to be work.

Others: Universal for Both Hands

Maintenance: It can be wiped and maintained with engine oil

Features

1---WUTA Professional leather groover tool,is a high grade tool for handing stitching grooves.

2---The Main Part made of H62 brass, connected to high density ebony wood handle,with natural texture and gloss, make sure the leather groover is in the best quality,durable and work well in the craft work.

3---3 size replaceable cutter head (1.0-1.5-2.0 mm) for different groover width.

4---The cutter head which made of M390 steel, hardness 61HRC,longer sharpness retention and non- rust,easy to shovel leather.

5---The L-shaped support material is 440c with excellent rust resistance and toughness. The heat treatment hardness of 55HRC can ensure that the strength and toughness are excellent enough. Moreover, in order to solve the problem of easy slippage during the use of the support, a higher-tech square support and square socket are used, which can greatly improve the stability of the support.

Advantages of M390

----M390 steel is one of the most popular and best performing types of steel on the market, it features in sharpness retention. M390 is so wear and tear resistant it also properly maintains the shape of the edge. As such a knife made from M390 steel will retain its sharpness for a very long time. This means you don't have to sharpen your knife as often. Not only great because sharpening your knife takes time, but also because it means your knife will last longer. After all, the more often you sharpen your knife, the faster it will wear out. It is not possible to sharpen a blade over its full height: the blade will become too thick behind the edge. This means it won't be as easy to use.

----In addition to sharpness retention M390 has a few other fine qualities. It can be hardened to a relatively high hardness without it breaking quickly. This, however, doesn't mean that M390 is very tough. It does mean that M390, when compared to other types of steel, can be sharpened a little thinner.

----M390 is also relatively stainless. Because of the large amount of chrome rust won't stand a chance. Especially when compared to other hard types of steel that are known for their sharpness retention but can still be affected by rust.

Welcome to drop any questions to us, thank you for looking!

The Main Part

Elaborately carved with H62 brass

Cutter Head

Adopt M390 steel, hardness 61HRC, effectively retain the blade sharpness for a very long time.

L-shaped Support

The support material is 440c with excellent rust resistance and toughness. The heat treatment hardness of 55HRC can ensure that the strength and toughness are excellent enough. Moreover, in order to solve the problem of easy slippage during the use of the support, a higher-tech square support and square socket are used, which can greatly improve the stability of the support.

Ebony Wood Handle

We adopt high density ebony wood to make sure the leather groover is in the best quality,durable and work well in the craft work.

Suitable for Left & Right Hand

01.Slotting on the front of the stitching position

Dig a groove about 1mm depth on the front of the stitching position. The specific depth and width are determined according to the thread thickness. then punched with chisel,and stitched to protect the sewing thread from abrasion.

02.Slotting on the back of the stitching position

Make a 1.5mm width groove on the leather back of the sewing position,the specific depth is depended on the leather thickness,then use bone folder to press the groove;finally punch hole in the groove line,it will reduce thread breaking and scratching leather.

03.Assist leather edge thinning

First Dig a slot according to the required width,then you can easily use wide edger or knife to cut an equal width.

04.Slotting in folded position

The place that needs to fold first uses the leather groover tool to dig a groove, can make folding position more natural.

Read Before Buying

- We are not responsible for any custom duty or import tax.

-

The real color of the item may be slightly different from the pictures shown on website caused by

many factors such as brightness of your monitor and light brightness.

-Once you don’t find all item you had ordered,please don’t throw away any of the

packing material, and contact us immediately. If you order the leather and the other small product,the small items maybe wrapped in a fiber container.

-The seller only accept refund for following reasons:

A.Quality problem

B.Send the wrong color,wrong item

C.Package damage or loss

-If you are not satisfied when you receive your item,please return it within 7days

for a resplacement or money back.Please contact us before you return it.The shipping fees is paid by buyer.

ONCE YOU PURCHASE THIS ITEM,IT SHOWS YOU AGREE FOR THESE

REGULATIONS,THANK YOU!